The era of industrial digital transformation is upon us, if the pace was quickening before with the pandemic its being accelerated unlike any other industrial revolution. While the world readies itself for IR4.0, the state where automation will no longer be a niche for just giant manufacturing firms and even the smallest of factory can operate remotely, the crucial element or the last puzzle will undoubtedly be…connectivity.

In order for mass machine to machine connectivity, artificial intelligence, automation and cloud servers to function seamlessly, a better, smoother and uninterrupted network is vital. This is where 5G steps in, the next telecommunication evolution that will propel the current technology to another level. Malaysia has been developing actively in this area since 2019 and we can see some of the progress being realised. U Mobile which is part of the telco consortium championing 5G has just performed a real time case scenario with high-tech contract manufacturer Hotayi Electronic in implementing mass workforce management solutions in two of its facilities in Penang.

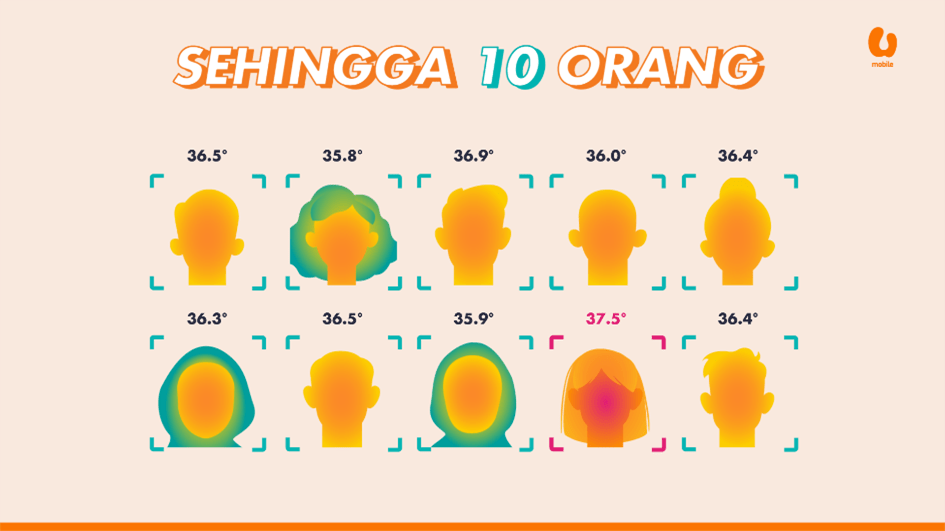

Using 5G, U Mobile tried out a Smart AI Facial Recognition system and a 5G-enabled Thermal Recognition whereby the system is able to capture structural features in real time as employees are entering the premise, they include age range, expression, gender and it can even discern if accessories like glasses or face masks are used. Key benefit for real-time solution is in the area of security as companies are able to program a white list/black list of personnel. Breaches will be detected immediately, and security team will be able to be alerted to act straight away. For thermal recognition solution, abnormalities in temperature reading are detected immediately and any abnormalities will immediately trigger the security team to take action.

Woon Ooi Yuen, U Mobile’s Chief Technology Officer, highlighted that these 5G use cases provided the telco insights into the potential of 5G applications in the manufacturing industry. “ In this scenario, we are delighted to have been able to collaborate with Hotayi Electronic, as well as our technology partner Huawei, to conduct use cases that improve the operational efficiencies through our 5G connectivity”

These case studies are feedbacks to MCMC the regulatory agency overseeing the country’s connectivity initiatives, as more industries prepare to enhance their facilities and operations in line with global trend, the need for Malaysia to take proactive steps in securing a lead in the new digital world is imperative.