Tapway Sdn. Bhd. today has introduced VisionTrack, an artificial intelligence (AI) Vision solution that helps manufacturers to improve product quality inspections.

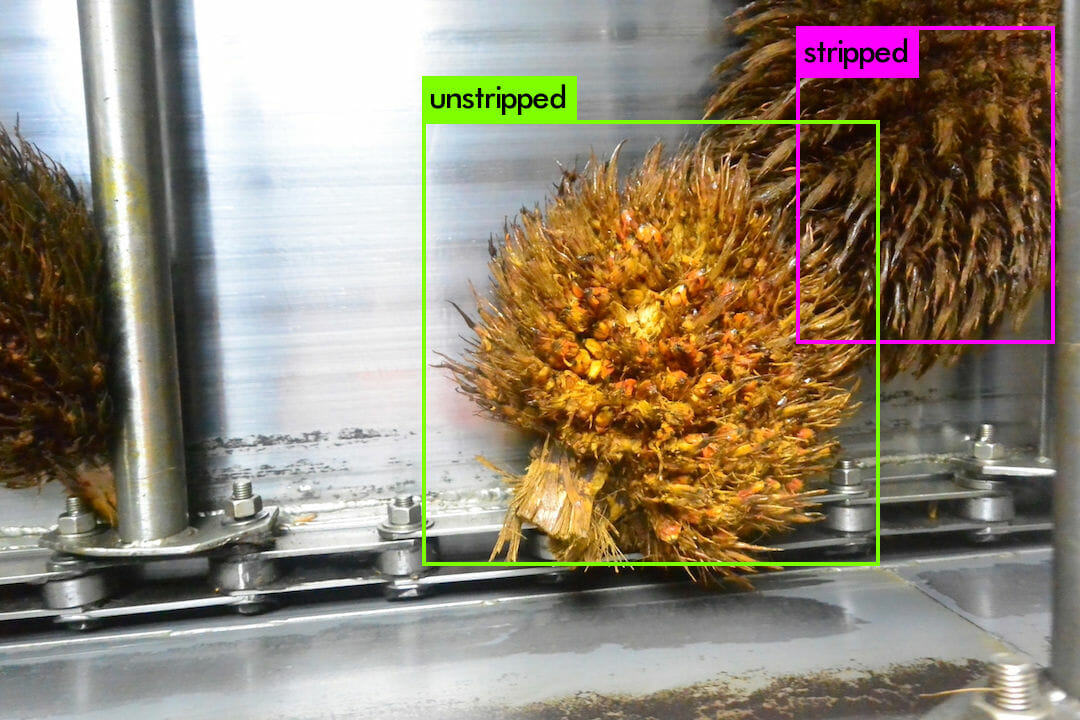

The new solution is an end-to-end visual inspection platform that allows anyone to train and deploy an AI Vision solution that can tackle the unique Quality Control (QC) requirements currently only possible by human inspectors.

It helps QC managers do their job more efficiently by automatically identifying defective products and/or performing product classification before the products escape the production line. By using VisionTrack, manufacturers can eliminate laborious tasks typically done manually. The VisionTrack platform is currently available directly from Tapway.

“Automation plays an important role in productivity as our economy is embracing industrial revolution 4.0 or IR4.0. Manufacturers can no longer rely solely on human labor to inspect thousands of products in a short period of time. Our VisionTrack platform can help manufacturers transform product inspections into a much more efficient process performed by trained computers. Not to mention the system is also more reliable without the risk of human error or fatigue,” says Lim Chee How, CEO of Tapway.

Tapway’s VisionTrack works for manufacturing businesses of any industry. Currently, Tapway is marketing the solution to manufacturers in the food & beverages (F&B) and plantation industries in Malaysia.

For VisionTrack to work, Tapway learns from how their human inspectors carry out their inspection and trains an AI Vision model that can comply with Quality standards stipulated by the manufacturer.

“For instance, in a factory producing bottled drinks, we will train a specialized AI Vision model and deploy this model to an edge server linked with camera(s) to find bottles with a dent, scratches or chip and send out an alert. It’s all done automatically by a smart system. AI Vision systems used to take months to train a highly accurate model, but with Tapway VisionTrack platform, you can train and deploy a model in a matter of days,” Chee How explains.