Volatile global market conditions are continuing to disrupt supply chains. In Gartner’s Emerging Risks Survey executives worldwide ranked these disruptions as the third-biggest risk to businesses this year after ransomware and post-pandemic talent issues. Despite an impressive post-pandemic recovery, supply chain disruptions pose significant risks to Singapore’s economic rebound.

The Singaporean government and local companies alike have turned to technology to increase the resilience of their supply chains and improve supply chain management. In 2023 and beyond, automation, blockchain, and data and analytics will continue to greatly influence supply chain management.

Complete supply chain visibility through blockchain tech

According to Deloitte, the lack of end-to-end visibility in global supply chains is a major challenge as importers place higher scrutiny on the source of their goods and need to respond swiftly to supply chain disruptions.

Distributed ledger technology, also known as blockchain, provides all parties in a supply chain with a single, real-time source of reliable information. All data that is fed in a blockchain, such as transaction details, are visible to all other parties at any time. Supply chain partners are assured of the information’s integrity through the security that has become synonymous with blockchain technology.

Automating exchanges of supply chain data removes the errors and inefficiencies associated with manual processes and physical documentation. All in all, blockchain technology will lead to significant improvements throughout the entire supply network, from greater resiliency to improved performance to shifted expectations among vendors, partners, and customers.

More efficient shipping, logistics, and delivery through automation

AI, and automation in general, can reduce logistical costs while making processes more efficient. The Singaporean government is currently exploring the feasibility of these solutions through the following:

- The Maritime and Port Authority (MPA) is developing an AI-powered system for ship docking. Using an algorithm that assesses data like available port berths and shipment types in real time, ships can receive custom docking recommendations that can lessen turnaround times.

- The Ministry of Transport (MOT) is encouraging the development of maritime applications of drone technology with the launch of the Maritime Drone Estate. This technology can enable surface-to-ship deliveries and remote inspections of maritime vessels.

The government also invested in the Supply Chain Initiative 4.0, which set out to integrate technology to help small and medium enterprises (SMEs) better cope with supply chain disruptions. This initiative explores the utilisation of AI in the early identification of disruptive trends, forecasting of demand for new products, and discovery of additional vulnerabilities.

Improved workforce productivity through upgrades in supply chain management software

Workplaces have been undergoing rapid digital transformations much like the supply chain management space. There is an undeniable trend of increased digitalisation and integration with new software solutions replacing legacy systems. Some features of these platforms include:

- Dashboards that combine supply chain managers’ most-performed tasks in a single view

- Project management, collaboration, and communication tools

- Real-time data and analytics

- Transportation management

- Dynamic inventory allocation and management

The most advanced of these platforms are designed with digital innovation in mind and can easily be integrated with emerging technology such as AI and the Internet of Things (IoT).

Automation across supply chains

Automation technology is increasingly used in every stage of the supply chain to the point where the possibility of autonomous supply chains is not too far in the future. Examples of automation’s impact include:

- AI in procurement can automate tasks currently performed by humans, including decision-making tasks such as spend analysis, supplier assessments, and compliance.

- 3D printing and robotics are already being applied in automated manufacturing processes, increasing efficiency while decreasing production timelines

- Automation will also enable a lean but more efficient workforce in the areas of freight forwarding, logistics, and delivery.

- Overall, autonomous supply networks will have increased reliability, reduction in human errors, be more cost-efficient, and have better compliance with sustainability regulations.

Automation will not result in displacing humans from supply chain operations entirely. Instead, it will increase the overall efficiency and productivity per individual worker as repetitive and tedious tasks are automated.

The role of the workforce in digital transformation

At the forefront of each enterprise’s digital adoption initiatives is its workforce. Employees must be set up for success with the ability to adjust to changing systems and user interface changes within applications in order to fully utilise the technology tools at their disposal and maximize the value of these investments for the organisation.

Decision-makers can help their employees become the engine of their company’s digital transformation success by simply helping them better harness the technology the company has already invested in. Digital adoption platforms (DAPs) can be used to provide a unified digital employee experience and step-by-step guidance across complex enterprise applications to preemptively resolve confusion while gaining valuable data insights. DAPs show employees how to fully use all of the digital technology at their fingertips right on their screens, precisely when they need it, boosting both the digital employee experience and productivity.

With a combination of these strategies, organisations can better apply automation, blockchain, and data and analytics to their supply chain management. These will enhance operational efficiency, reduce costs, improve turnaround times, and drive desired business outcomes.

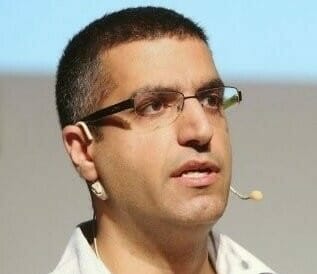

By Uzi Dvir, Chief Information Officer, WalkMe